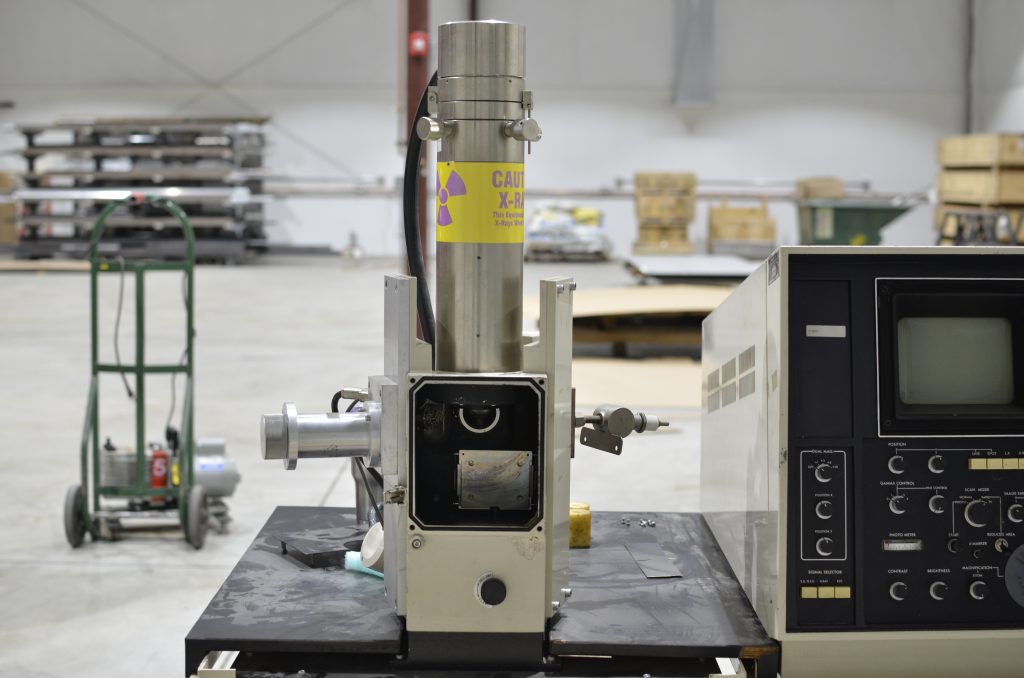

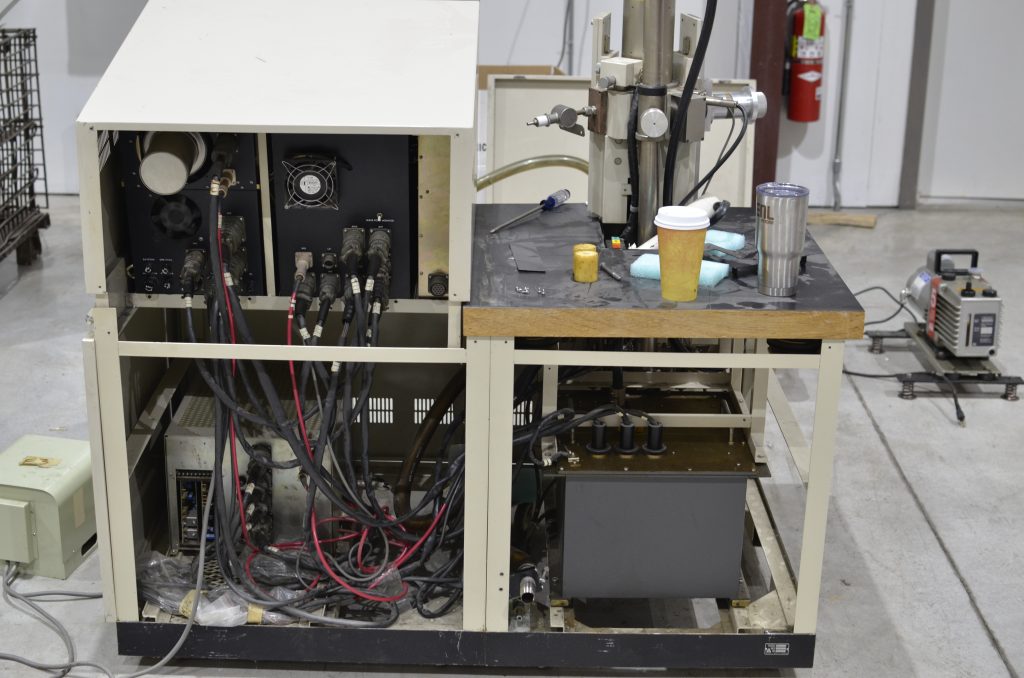

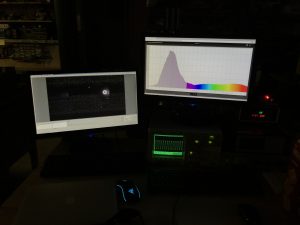

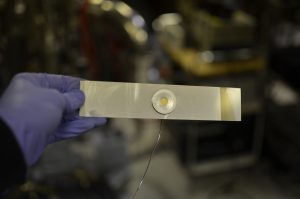

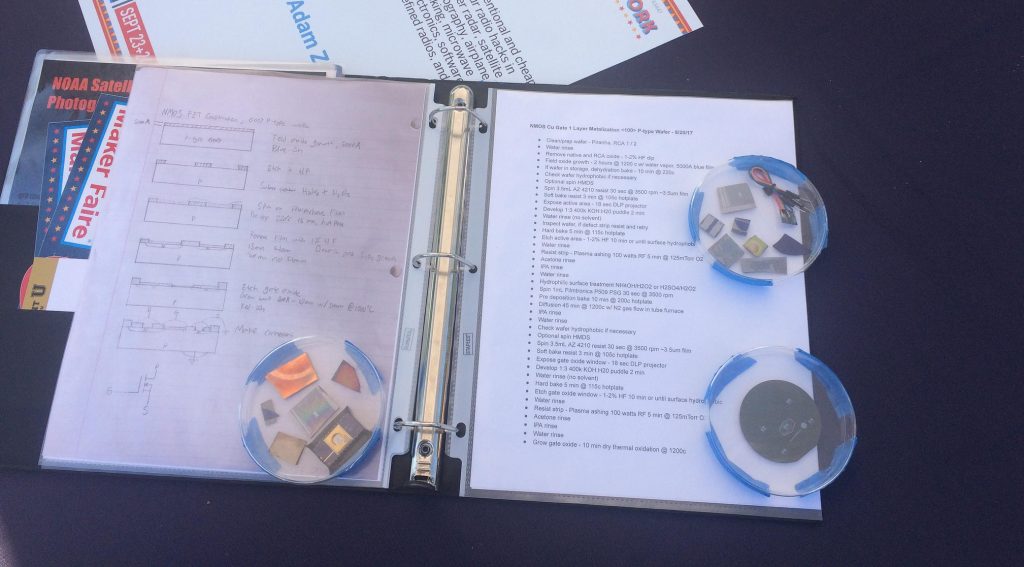

Lift-off is a technique that allows you to patten a metal layer without any etchant chemicals. Photoresist is spun on, exposed, and developed then the metal is sputtered or evaporated on top of the resist. The photoresist is then striped and any metal on top of it is peeled off. This leaves metal in only the areas in which the resist was not present after developing.

Typically, negative photoresist is preferred for lift-off for a number of reasons but I did not want to change my existing process so I attempted it with positive AZ4210 resist yielding decent results.

Photoresist can be removed in acetone or developer solution (assuming it is exposed by ambient light during processing) but a lower vapor-pressure solvent is preferred. An ultrasonic bath can also improve lift-off.

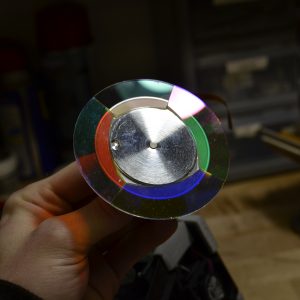

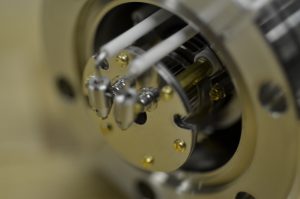

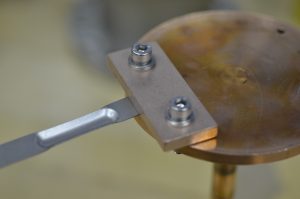

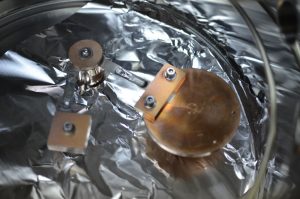

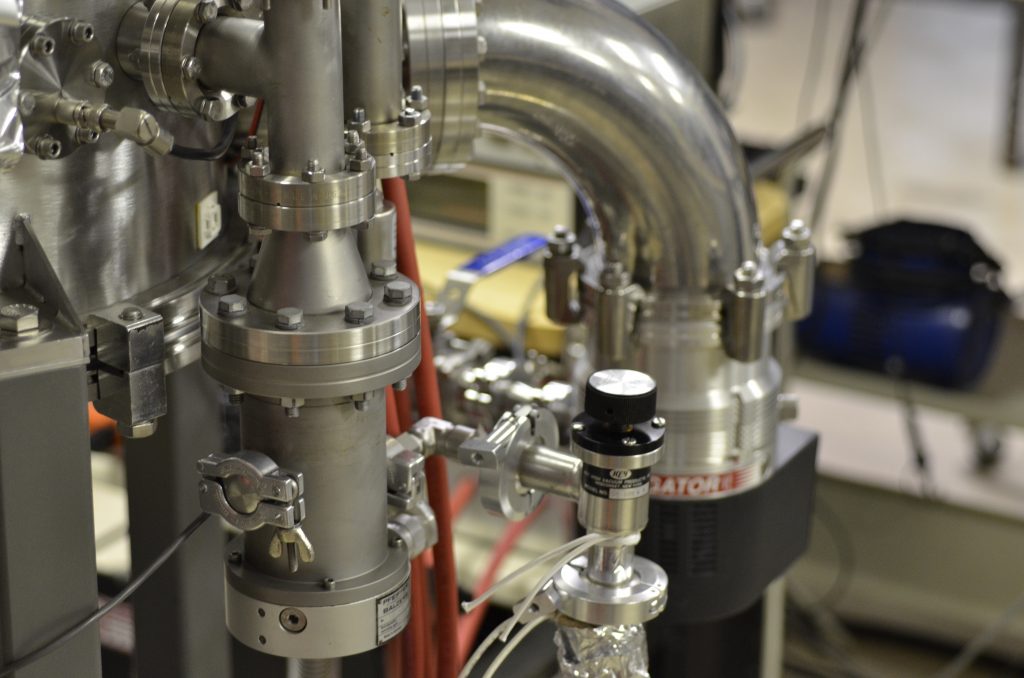

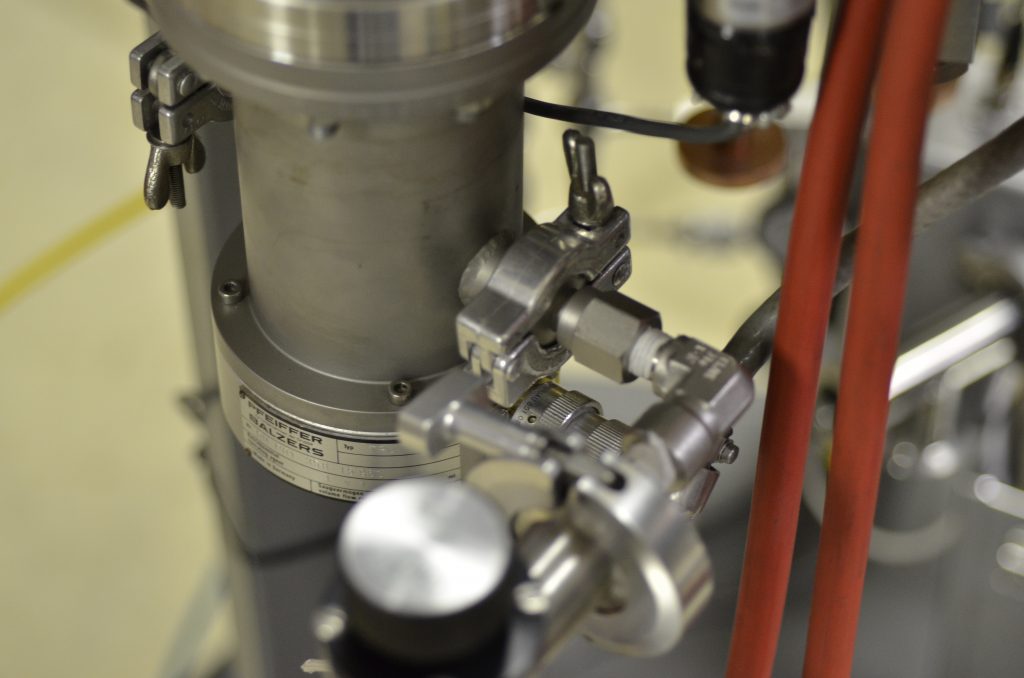

If lift-off is difficult, a thicker resist film or thinner metal coating can help. Also, substrate heating during deposition leads to resist softening and side wall coating, making lift-off impossible. I used a Peltier cooler in my chamber to prevent this.