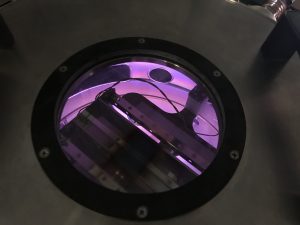

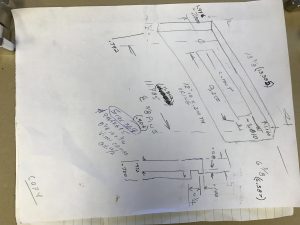

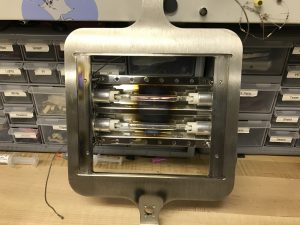

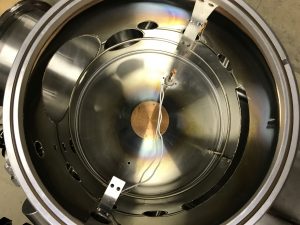

I machined a delrin insulator with fiberglass center rod for the CF 4 pin electrical feedthrough to provide power to the two incandescent substrate heaters in my new sputtering setup and to allow for instrumentation hookup.

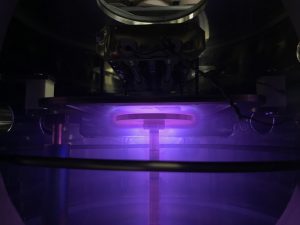

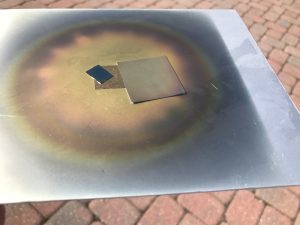

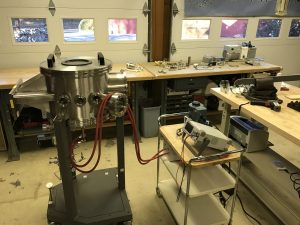

New sputtering setup has dual substrate heaters as well as insulated feedthroughs for both target and substrate so that it can operate in DC, RF, Bias sputtering modes, or any combination therein. A quartz microbalance thickness monitor will be added soon.

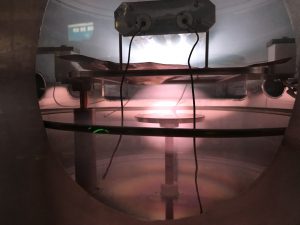

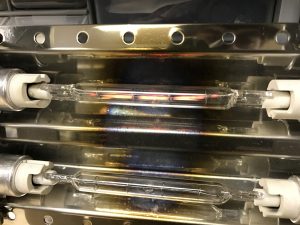

The second to last image shows multiple colors in glow discharge during sputtering possibly due to DC bias. Bottom and top electrodes are both at different potentials with respect to chamber ground, so it is possible that different gasses are ionized due to differences in ionization energies of the residual gaseous species.