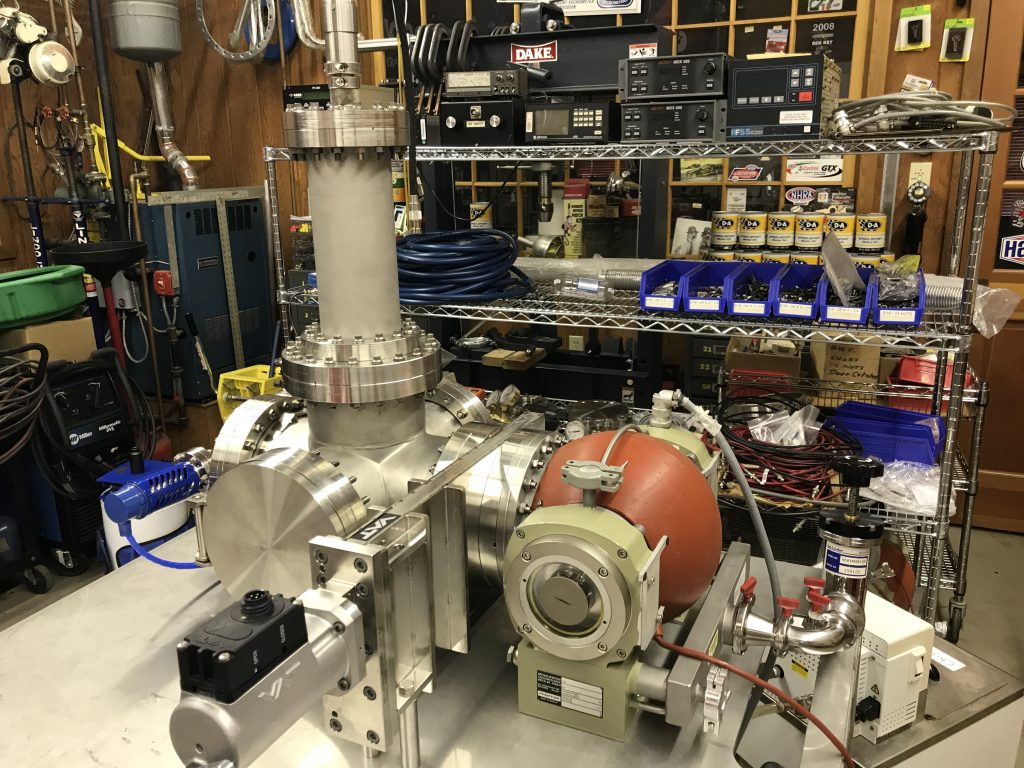

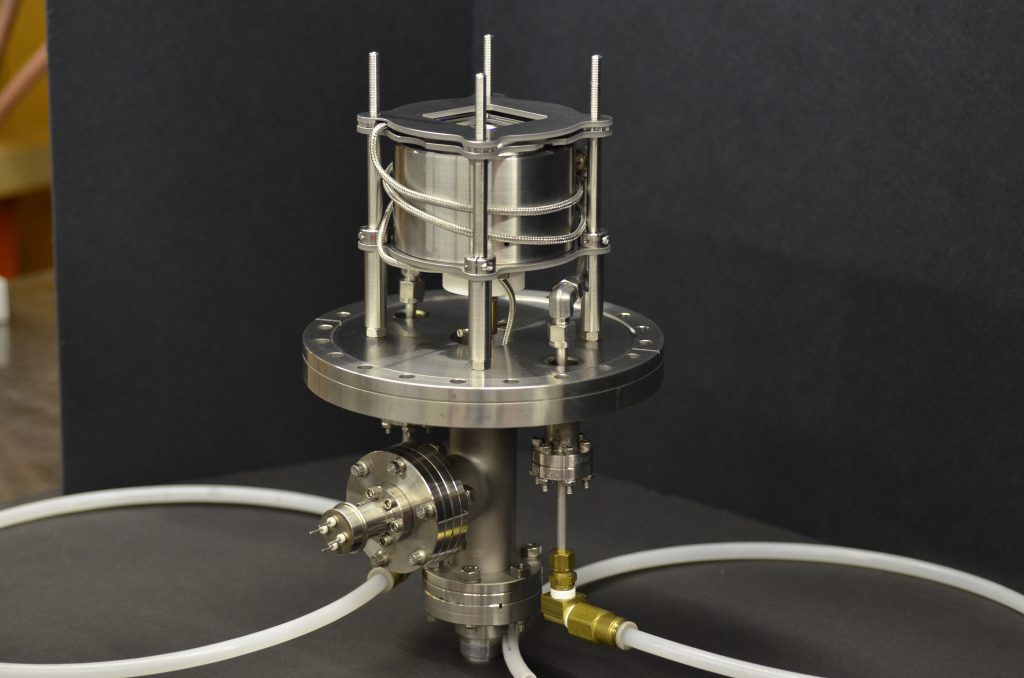

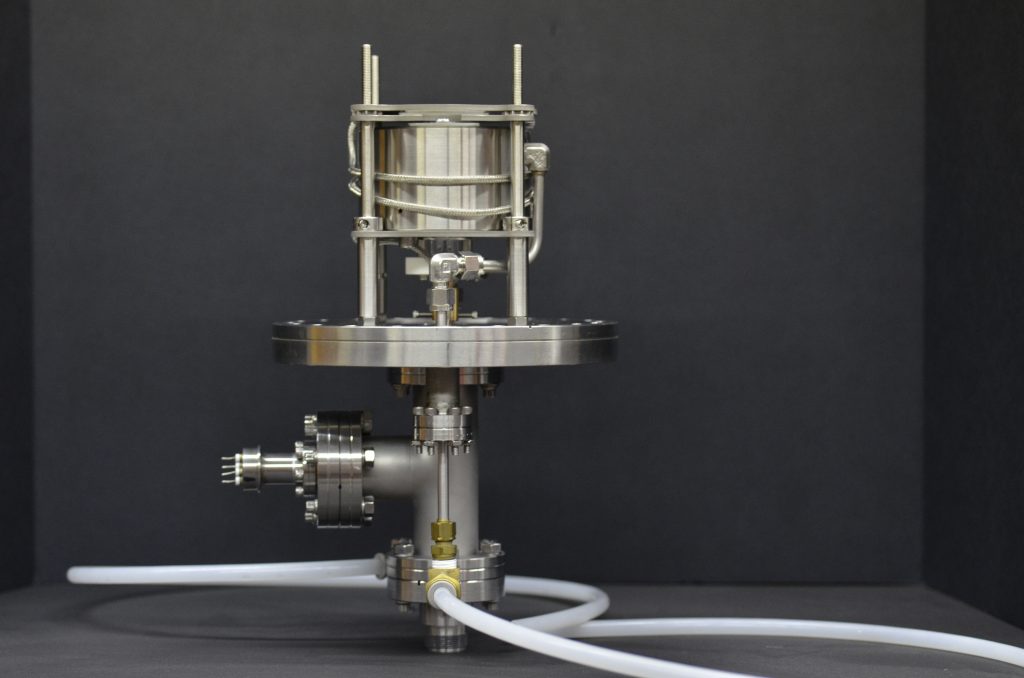

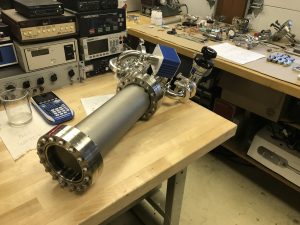

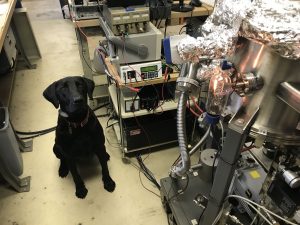

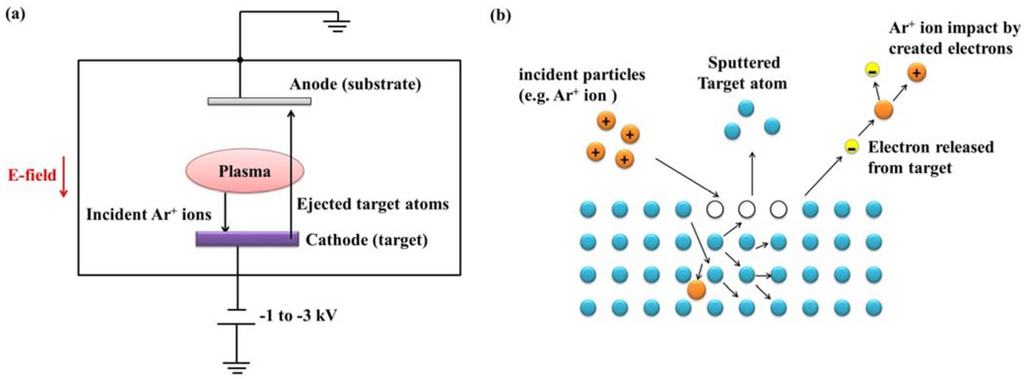

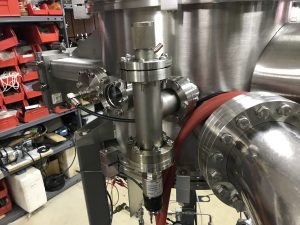

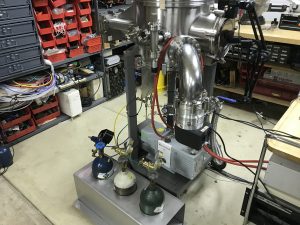

This project involved developing a sputtering system in collaboration with Ilya Drozdov in the Oxide Molecular Beam Epitaxy / Condensed Matter Physics Group at the Brookhaven National Laboratory. This system has 2 process gas feeds, an infrared substrate heater, and is designed for low-rate coatings that last 2 weeks each.

You can see other services that I offer here

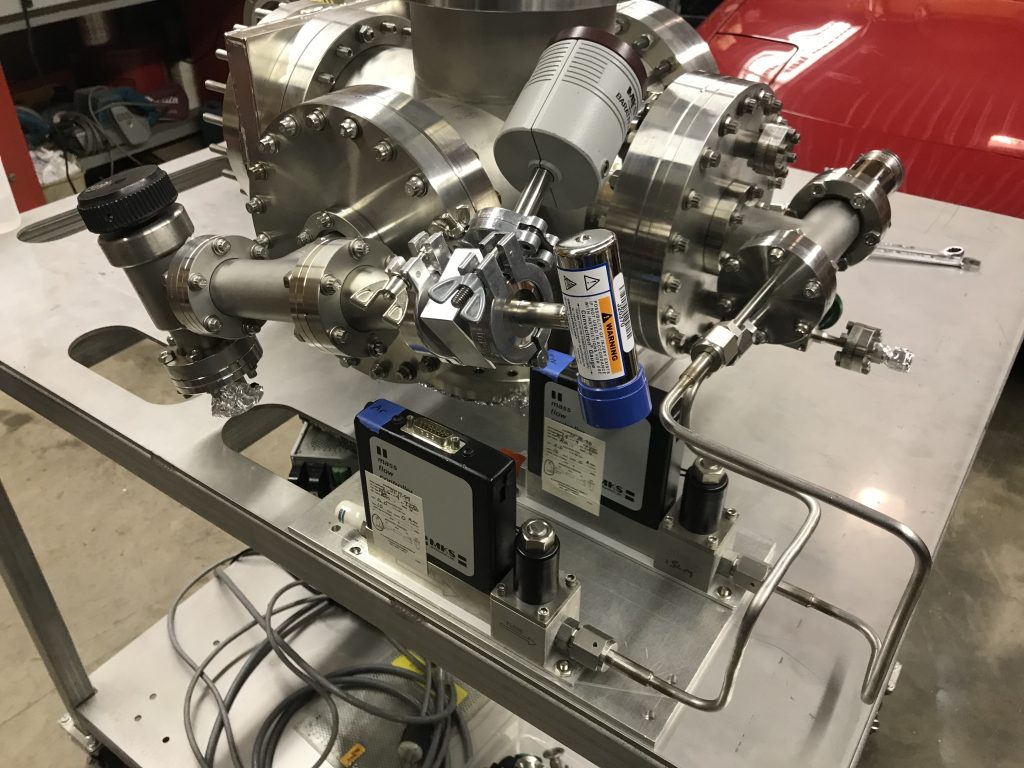

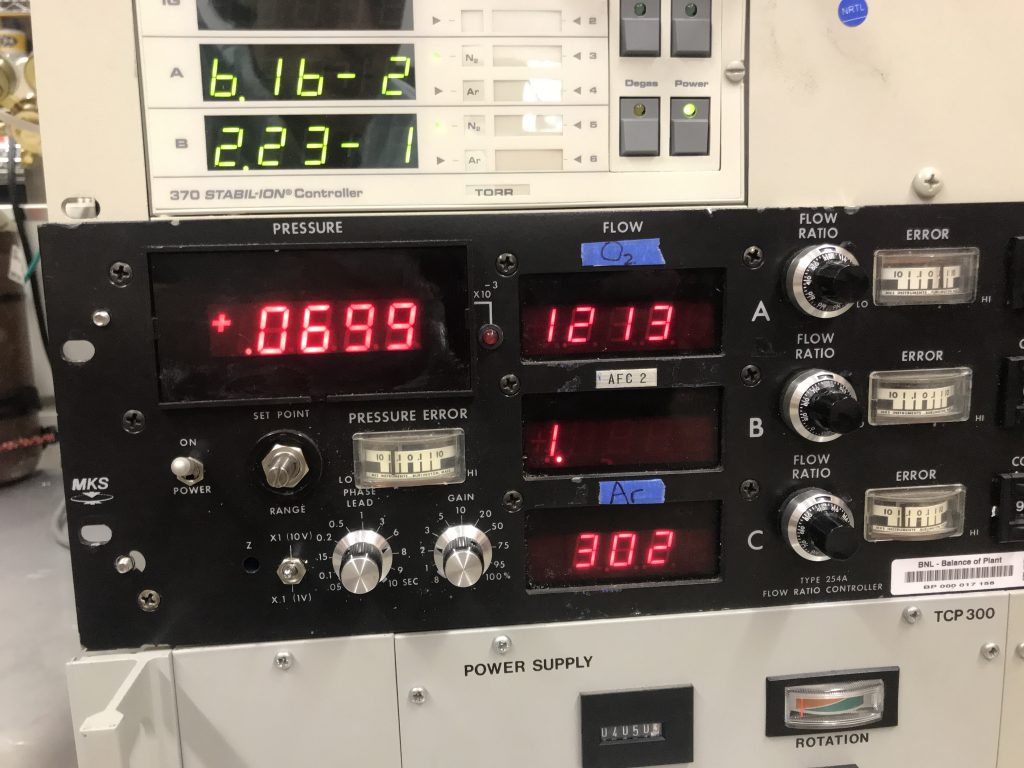

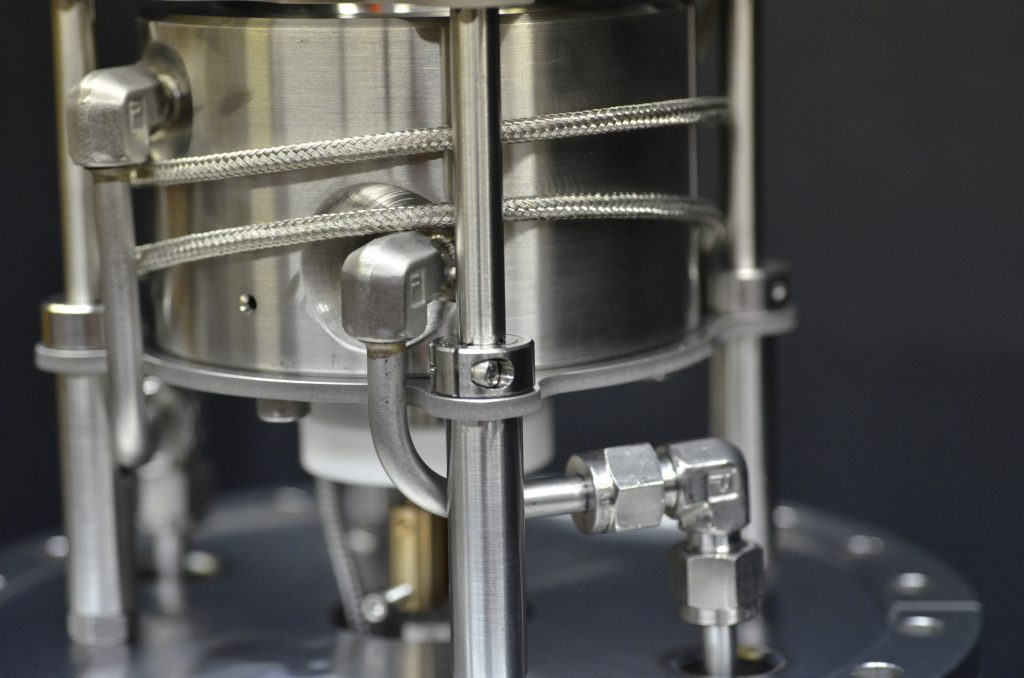

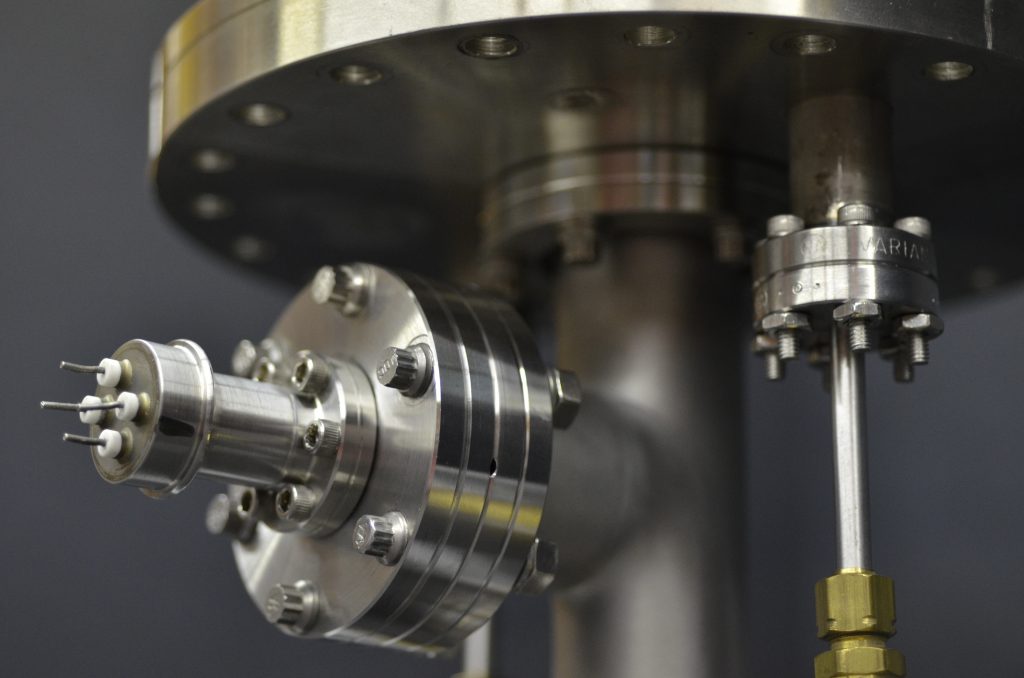

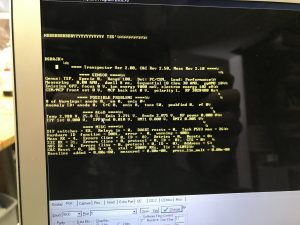

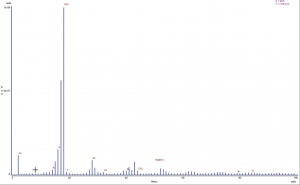

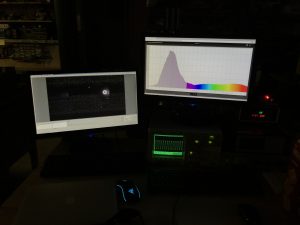

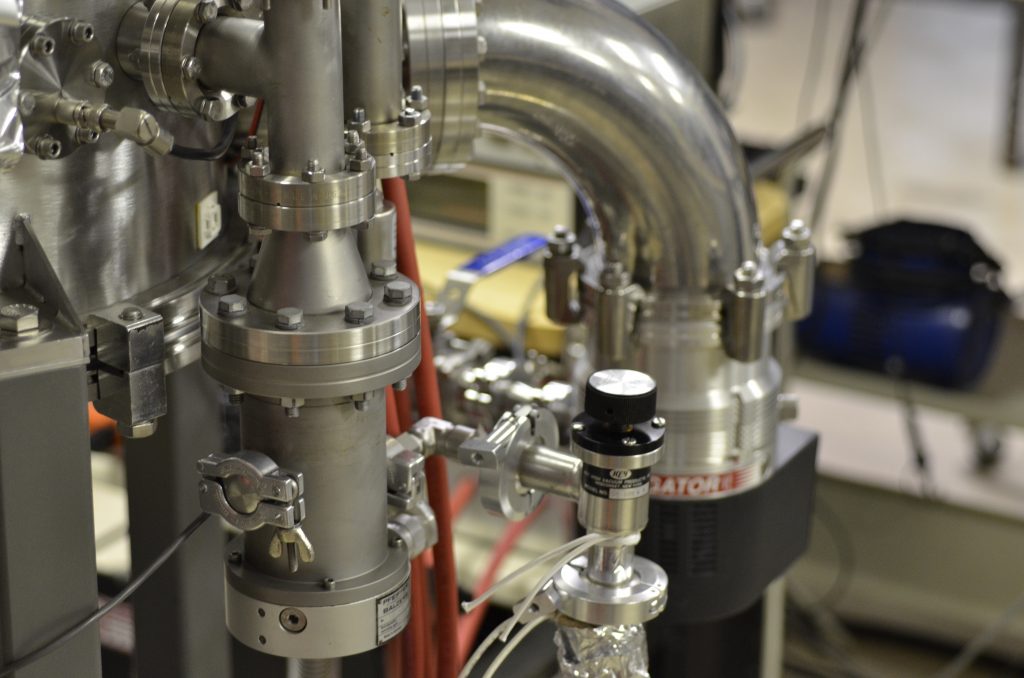

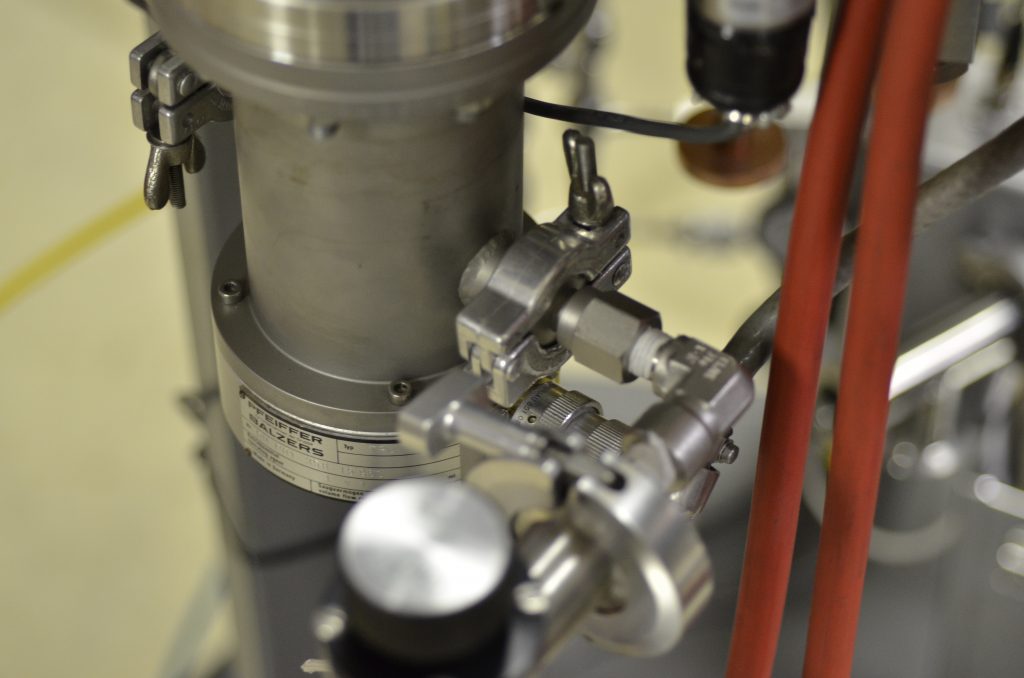

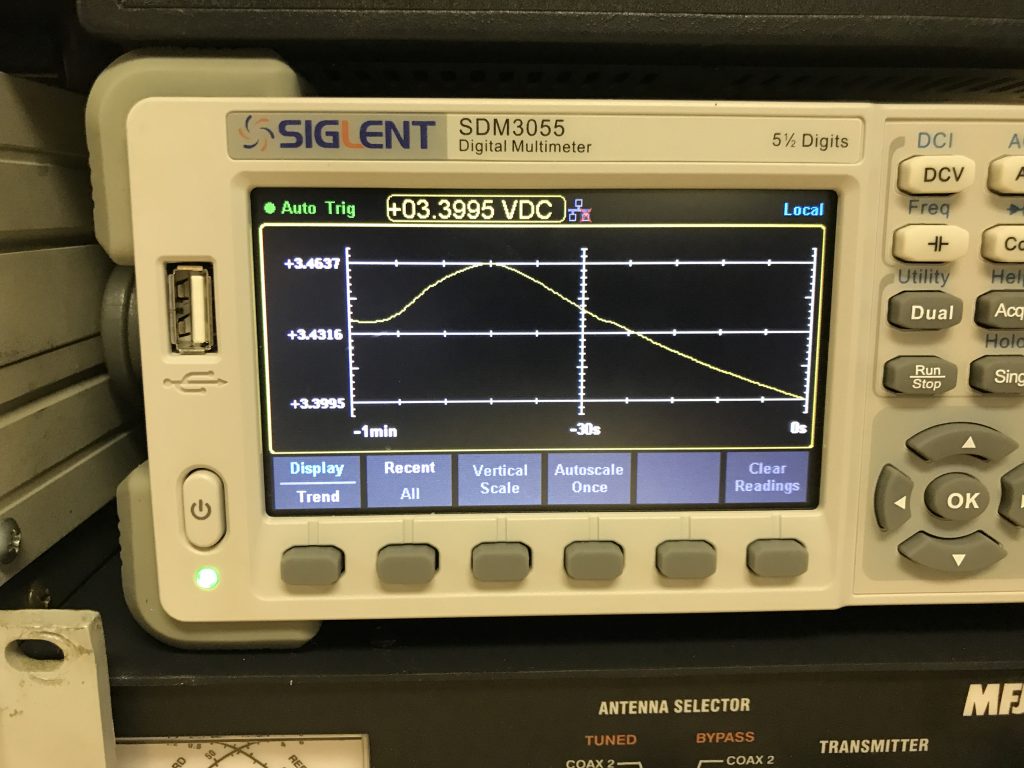

The vacuum system consists of a large dual turbo pump (510L/s) backed by a scroll pump and throttled with an 8″ VAT gate valve. The process requires O2 and Ar lines on Mass Flow Controllers plumbed in as well. The MKS controller drives the MFCs to flow in the process gasses in the correct ratios and keep the pressure within 1% of the setpoint.

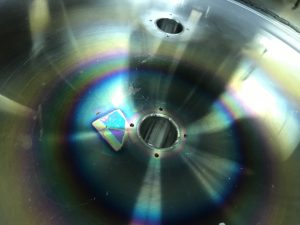

The chamber is quickly evacuated to the 1e-7 Torr range although the actual process occurs around 50 – 100mTorr under O2/Ar atmosphere.

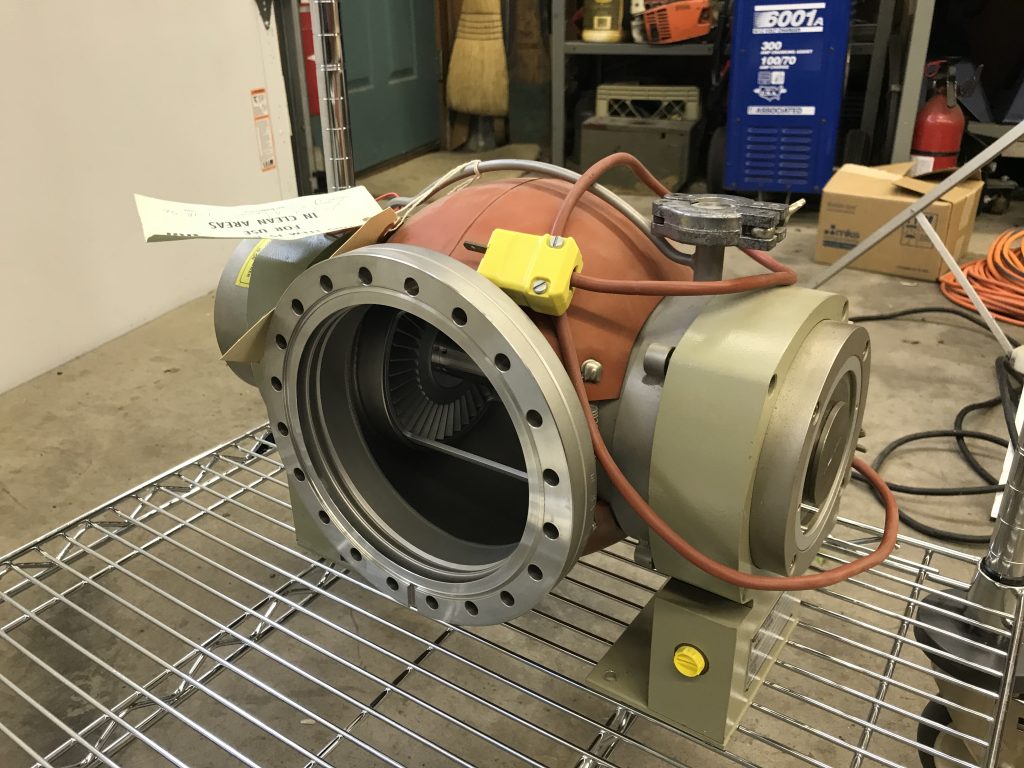

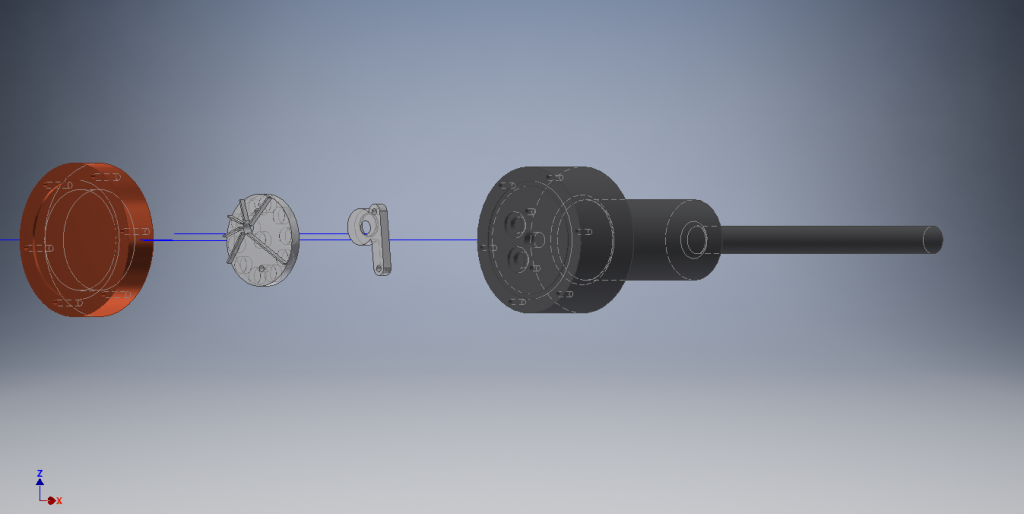

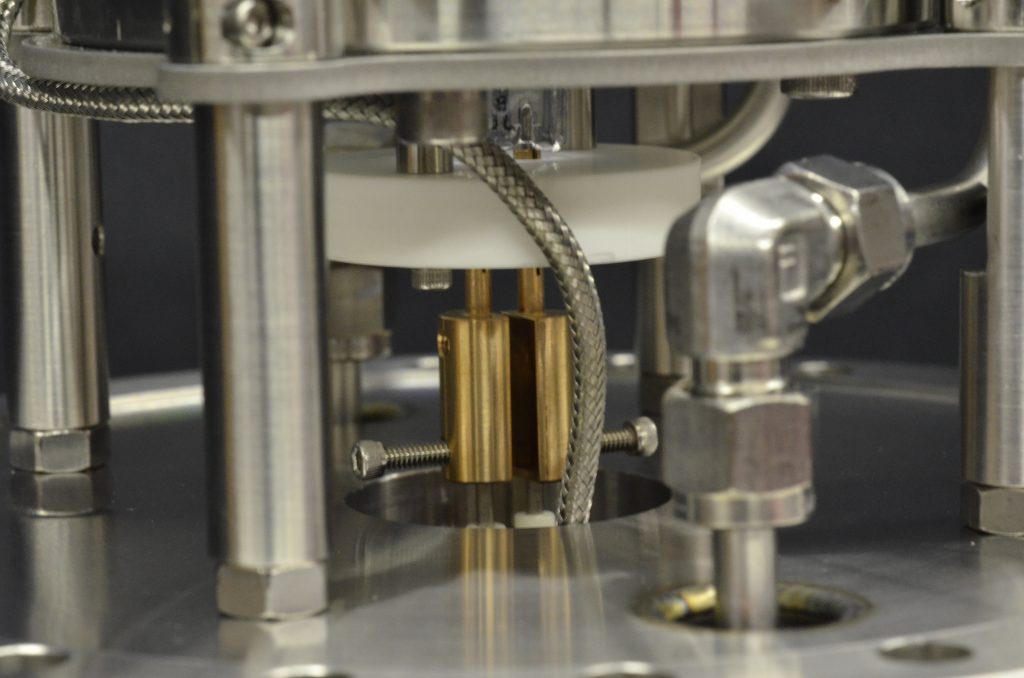

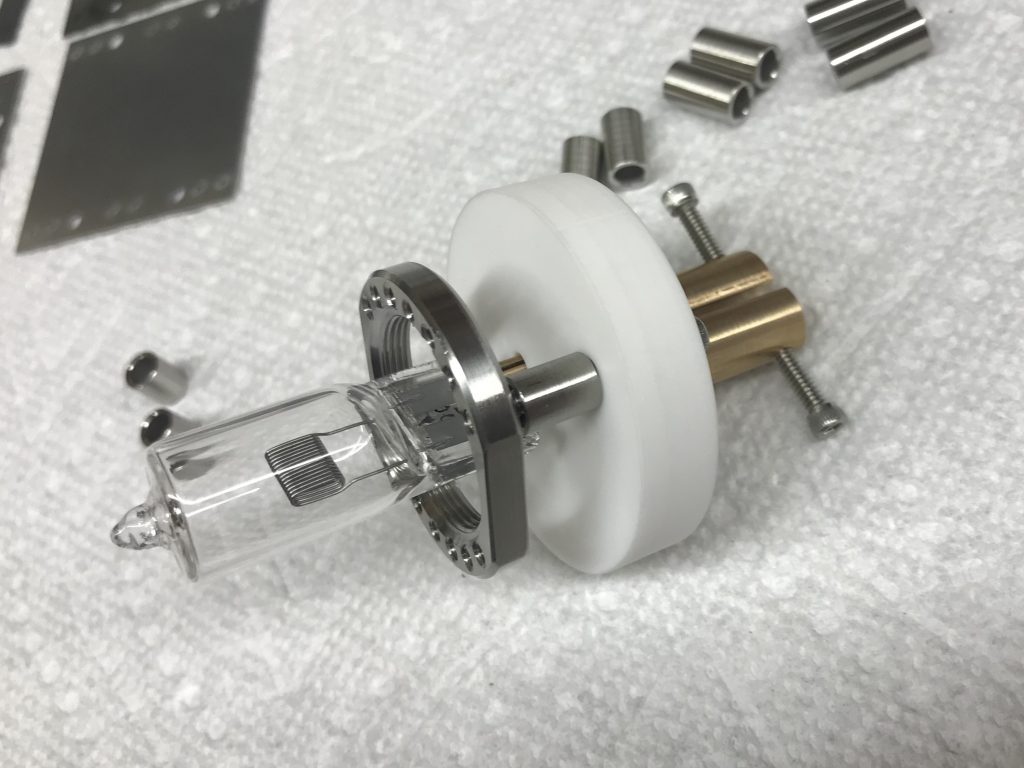

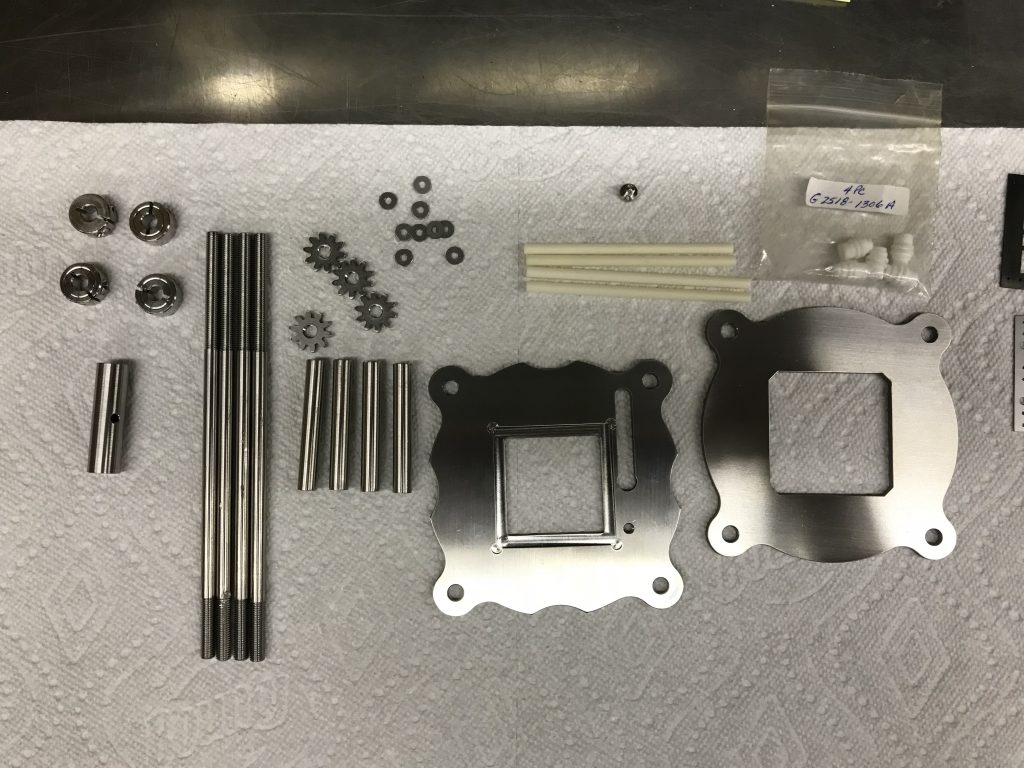

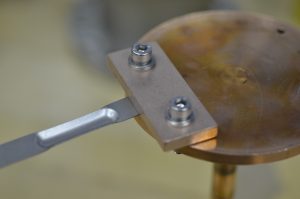

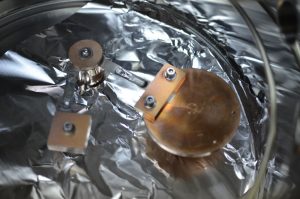

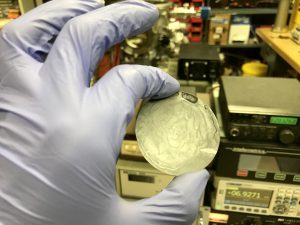

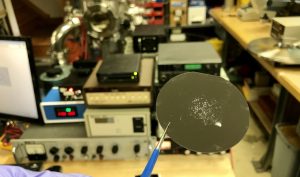

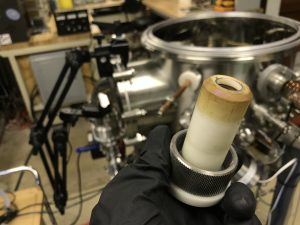

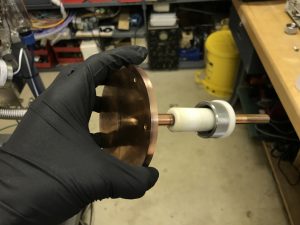

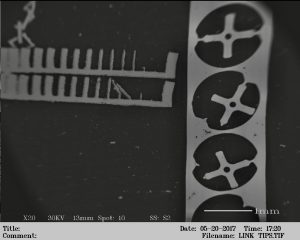

The 3″ dia. sputter gun was salvaged from combining old stock of broken ones together and making one functioning sputter gun.

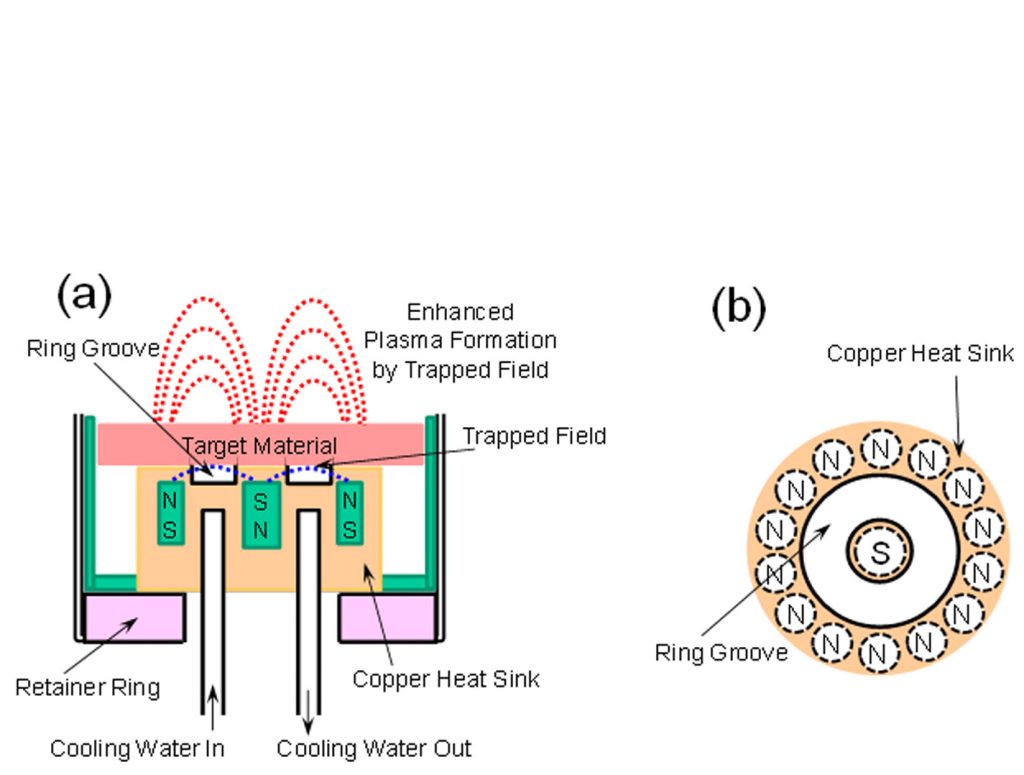

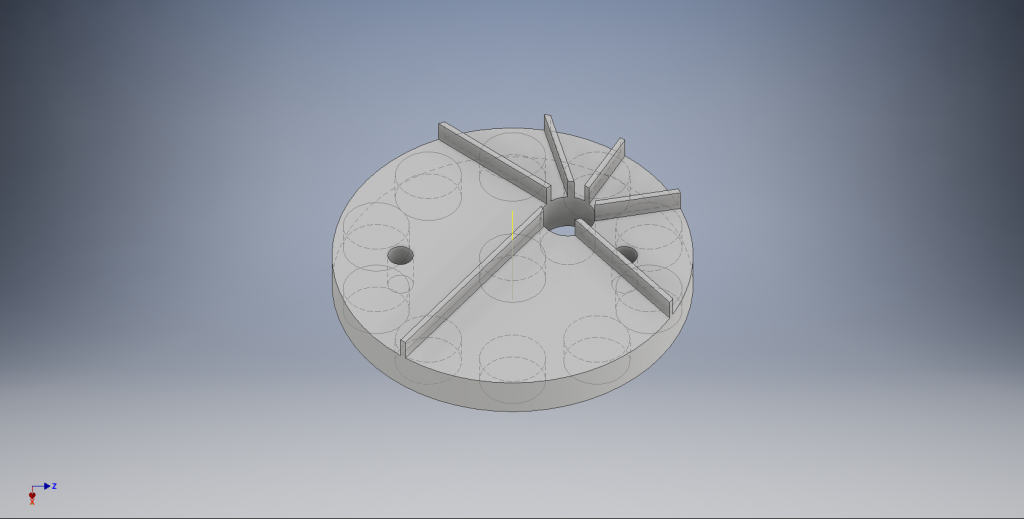

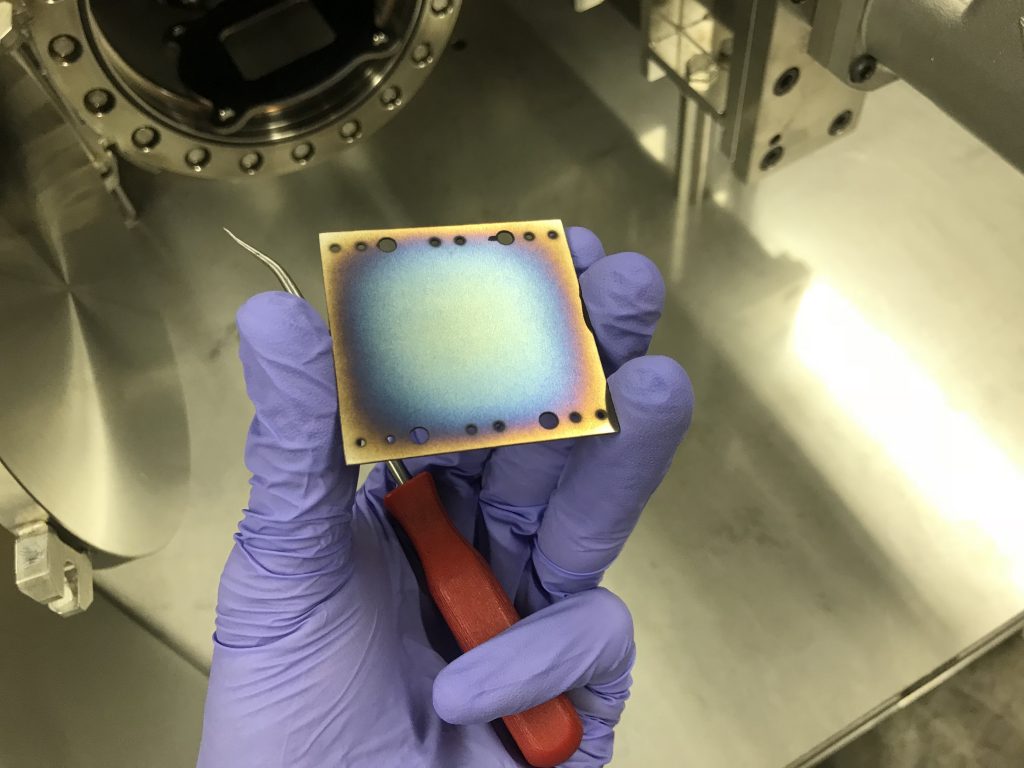

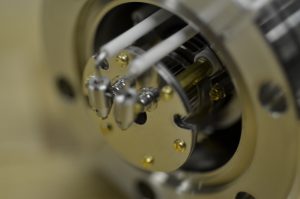

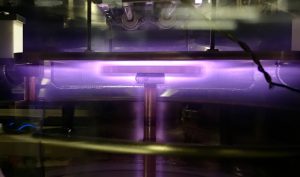

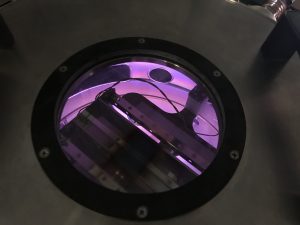

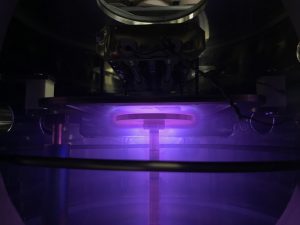

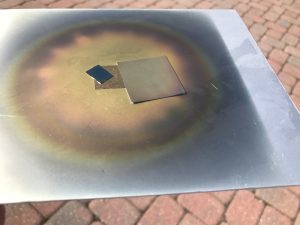

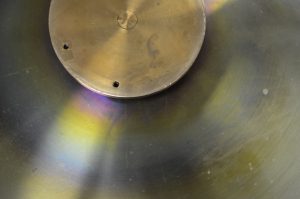

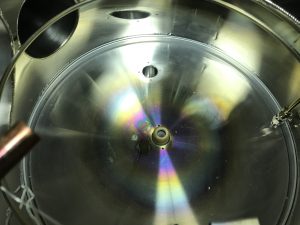

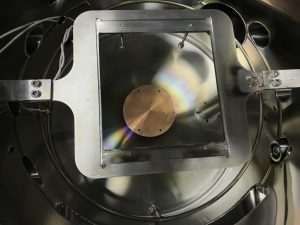

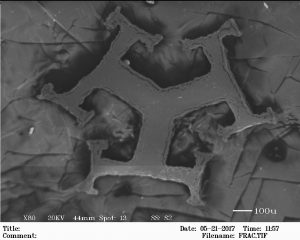

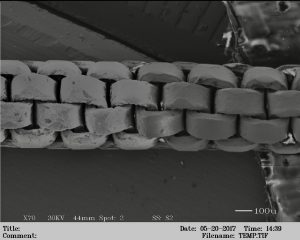

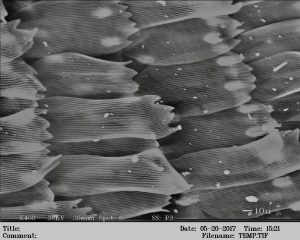

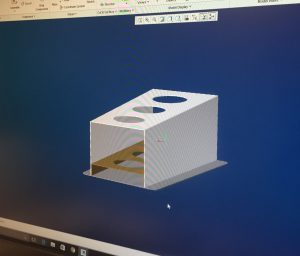

The sputter target is clamped to the Copper puck which is water cooled because of the high power involved in these sputtering processes. All of the sputter gun parts I started with had rusted magnet assemblies, so I had to make a new one. A 3D printed puck that fits inside the copper piece was designed with embedded rare Earth magnets to create a surface DC field of around 400 Gauss which confines electron movement and induces the magnetron effect.

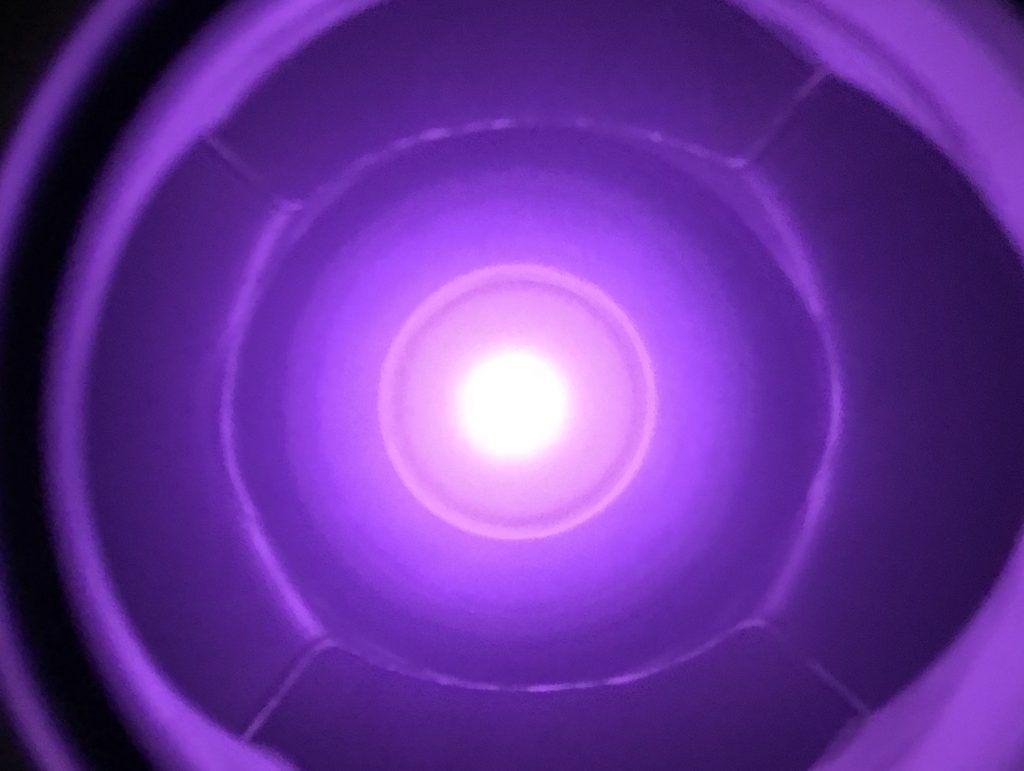

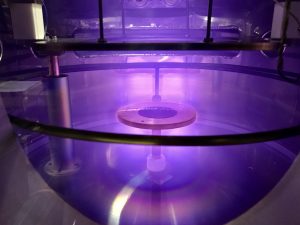

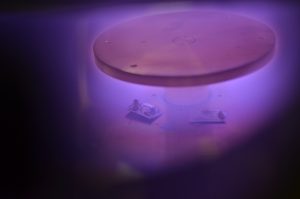

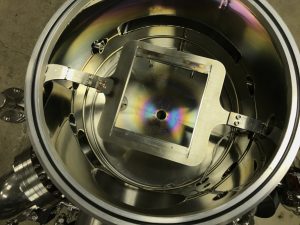

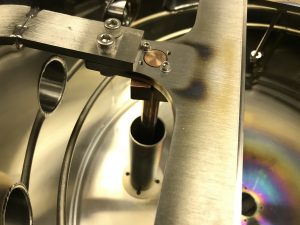

The “racetrack” ring-like plasma density in front of the target indicates the circular path of the electrons due to the Lorentz force, meaning that the magnet assembly has sufficient strength at the surface of the target.

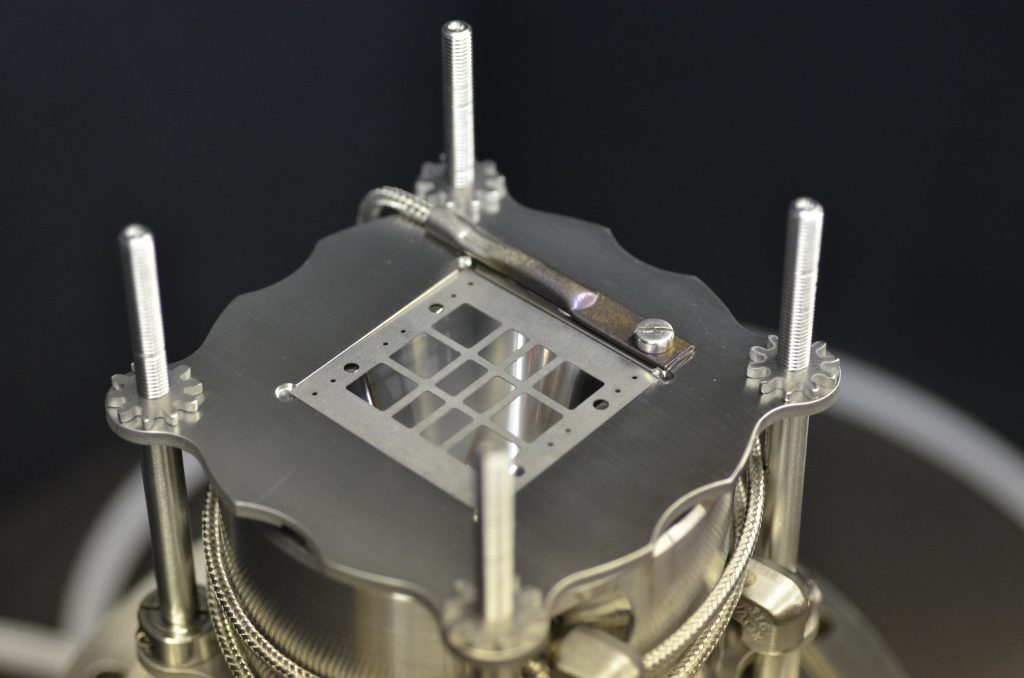

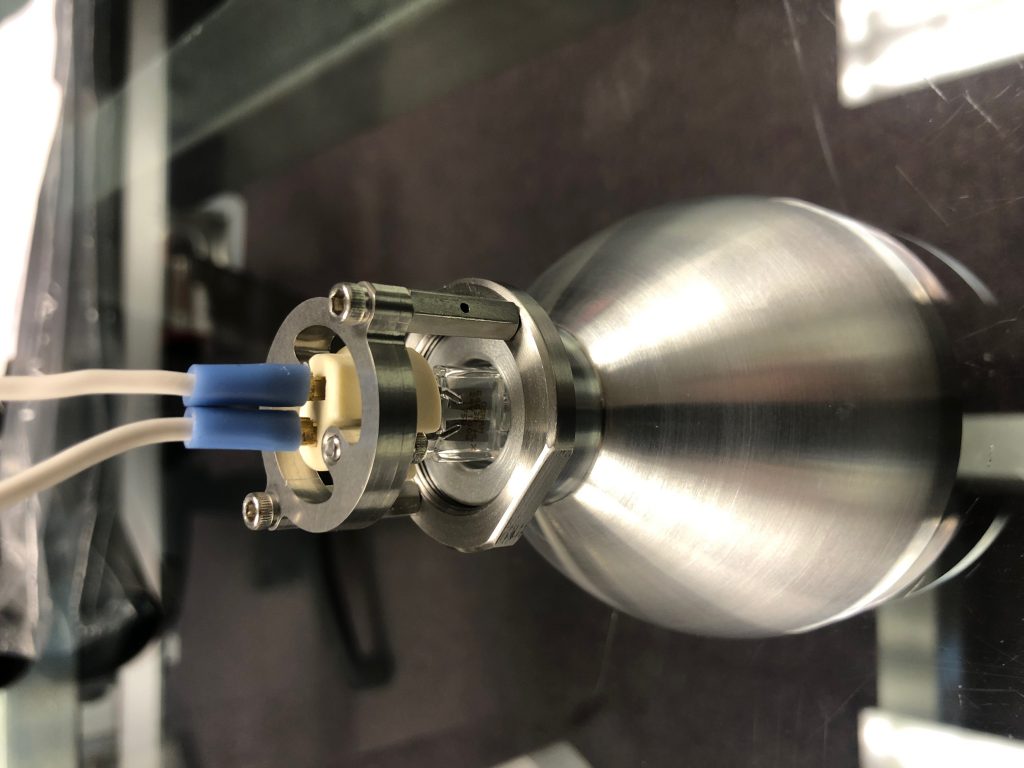

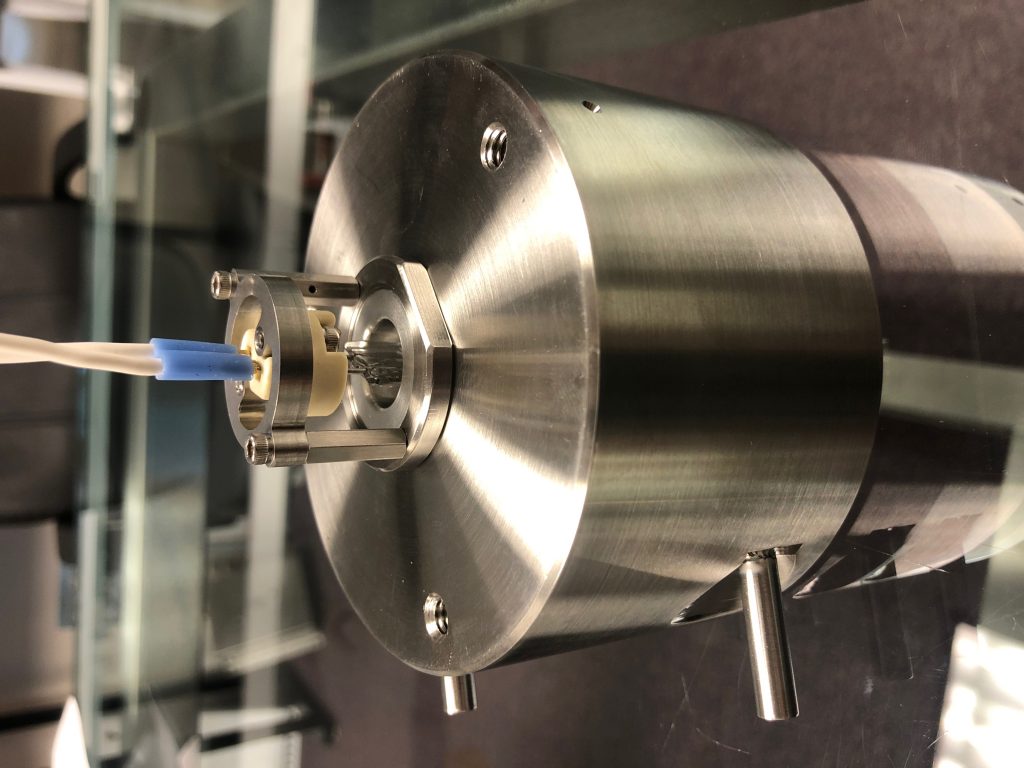

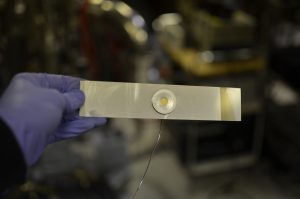

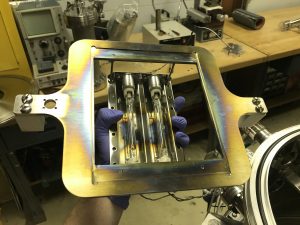

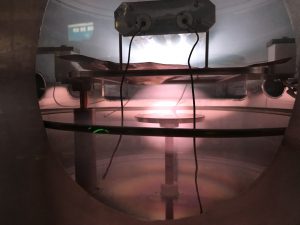

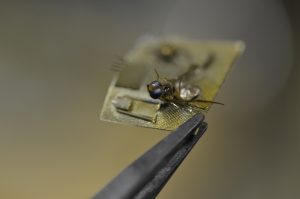

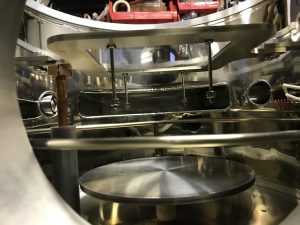

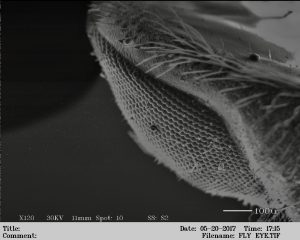

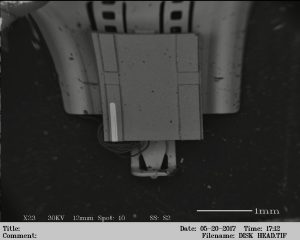

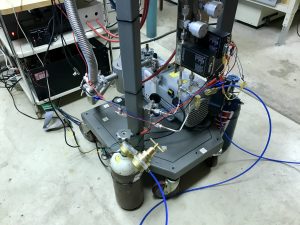

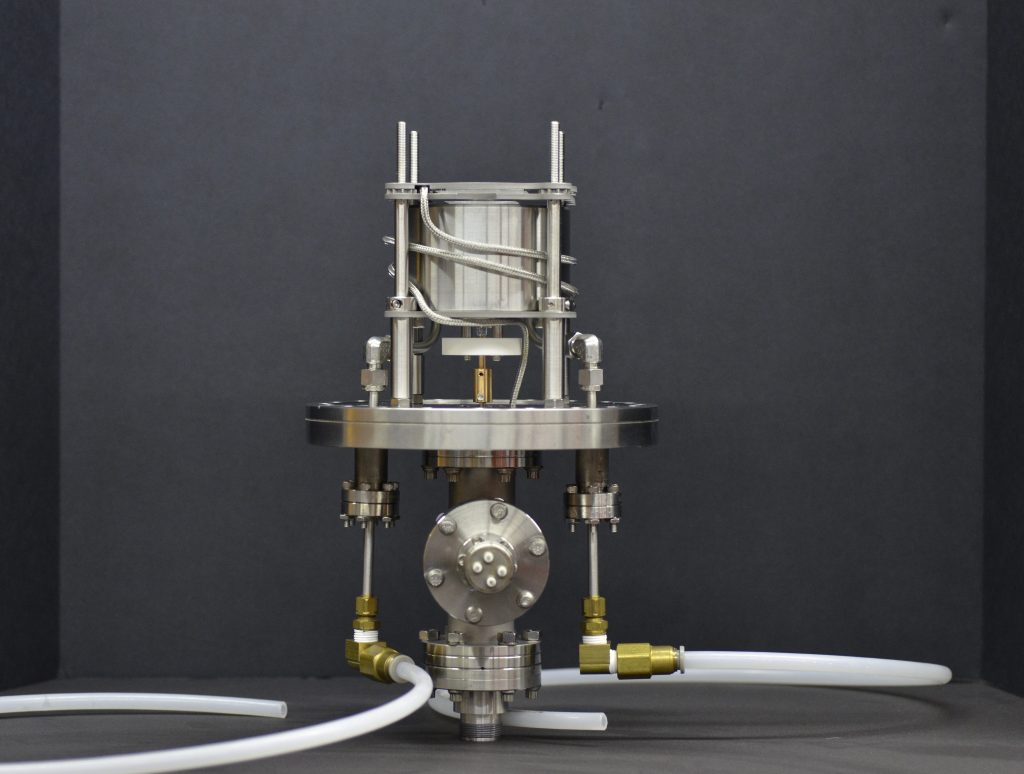

The final part of the project was the substrate heater which heats the sample from the back while it is being coated from the front. The specific process required that the substrate to be at elevated temperature (up to 850C) for 2 weeks. An infrared substrate heater was designed using 300W USHIO quartz lamps and a water cooled Aluminum parabolic reflector to focus the light onto the substrate.

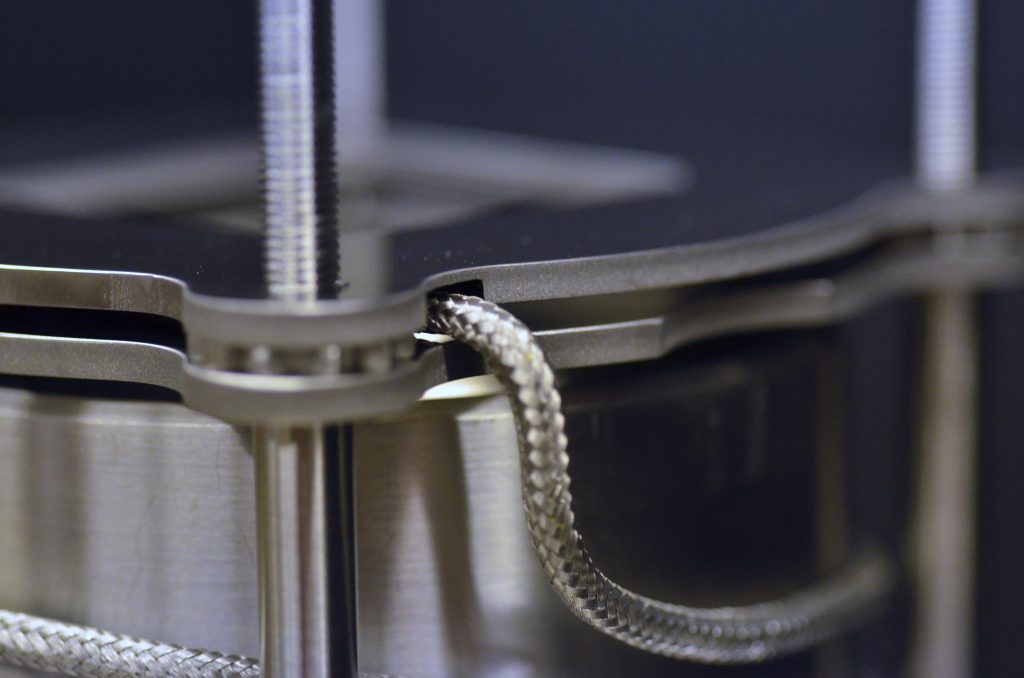

All parts of the heater which are exposed to elevated temperature are made from Inconel to avoid contamination of the delicate experiments. This includes the thermocouple, which is sheathed in Inconel and the wires are braided in Inconel as well.