A quick attempt making a titanium sublimation pump. Ti welding rod was bent into a coil around aluminum round stock and placed across 30-50 amps in high vacuum yielding successful results. Chamber was roughed down to 20mTorr then pumped with turbo to 1e-5 and briefly baked out. More testing will be done and results will be posted along with an updated design with shielding to make it into an actual pump rather than depositing all over the chamber walls.

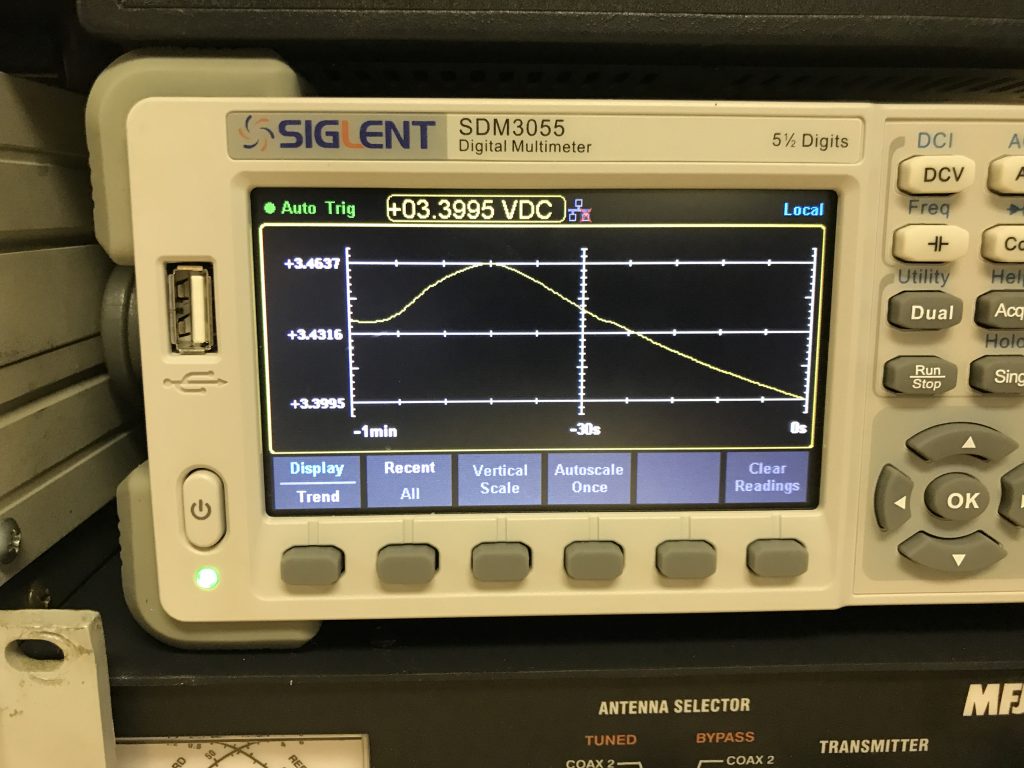

During testing I experienced a strange pumping curve a few times as shown in the last picture where the filament while heated at 50 amps seemed to out gas twice before reaching sublimation.

(Click on image to enlarge)

The basic idea of a TSP or getter pump is that the filament is heated past 900 degrees c with a high current across it. The filament first out gases and raises the chamber pressure, but then reaches sublimation pressure where it begins to form a thin volatile coating of Ti on the chamber walls.

Titanium, in this heated state, will readily combine with gaseous specious in the chamber to form a more stable coating and the gas molecules in the chamber basically get incorporated into a thin film on the chamber walls and trapped. The filament current is cycled for highest effectiveness. A rewound MOT is used for high current supply.

Good technique. Really interesting.

I have few quick queries.

What order of vacuum was achievable using this TSP?

What was the thickness of the layer of Titanium inside the chamber?

How much time did the first layer last before the second round of coating was done?

Any report that I can refer to ?

Regards

Sunil